Dillon RL550 Reloading Machine Review

UPDATE 2019: I still have the Dillon RL550, and still use it some. The problems I had for some time were resolved by about 75% by replacing small parts and springs that should have worked far past the point they did. It is tolerable enough to use it when needed now, but it has never produced a love for reloading in me.

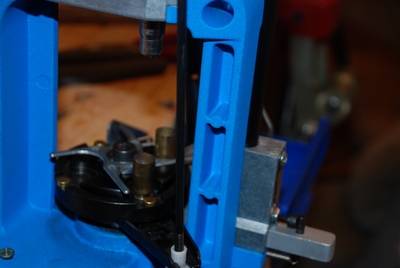

The picture below, which includes my Dillon RL550, is my little corner of the reloading world. Actually, as much as I try to keep my reloading station clean and tidy, it ends up looking like the city dump. But that's another article.

The Dillon RL550 was purchased to add speed and volume to my reloading, upgrading from my Lee Classic Turret press with auto indexing, which I still have and use for a couple of loads. The review contains updates for a couple of years.

Today's update 6/2012: I'm still using the Dillon with significantly more speed and less trouble since finding out the simple act of leaving the primer tube cap loose would solve some of the problems listed below.

ANOTHER UPDATE 1/26/2011 on the Dillon 550 reloading press. Well for all I've written below. For all the "expert" advice I've gotten on how to "tweak" the machine to get the infernal priming system to work, the most valuable piece of advice came from a forum (which is a rarity).

For all of the "send it back to have it "tuned", to using a rubber band just so to make it work, the best piece of advice is not found in any documentation that I know of.

Here it is: "Don't tighten down the primer tube cap all the way. Leave it backed off a couple of turns." How about that?

Doing that did not make the process perfect. It did, however, make my reloading so much more efficient and reduced the problems by such a margin I don't hardly mind a few tweaks now and then.

The Dillon, by general design obviously works to turn out good amounts of ammunition. But Dillon would do well to include troubleshooting documentation and significantly improved instructions with their machines.

Obviously the Dillon 550 reloading press is not manufactured with the intent of "not screwing down the primer tube cap." But that's the way it works best.

Other problems are accounted for by the difference in primer hardness. In any case I am loading at least 50% more trouble free than before that one simple piece of "tweaking" advice.

{NOTE: Update 11/29/2010 - (The original Dillon RL550 reloader review starts below this paragrah). It's now almost the end of 2010. When I wrote the original review, I was a neophyte with the Dillon.

Not now.

Otherwise, nothing about the machine has changed. The primer system is still a monster to get working right. And that's after a couple more years experience, and every kind of advice imaginable sent to me telling my how to "tweak" the machine. That included one person who told me how to attach a rubber band to make it work better.

But that's the whole point.

The machine has a primer system that continually has to be "tweaked" without any consistent reason that it breaks down endlessly. I'm all for changing this review to something positive if anybody can give me a fix-all for it.

Until then, I still grudgingly acknowledge that I can reload faster with it than with my former Lee machine. But it's not because I like it.}

There are a million good videos on YouTube that show in detail how to set up and load with all Dillon machines. So, there's no reason for me to do that here. Consequently, just like with the gun reviews, I'm going to show you the basics of how it works, and give my evaluation on it based on how well mine works and what I've been able to do with it as of September 2008.

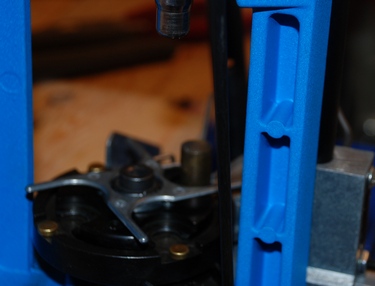

These are tool heads ready with dies of various calibers.

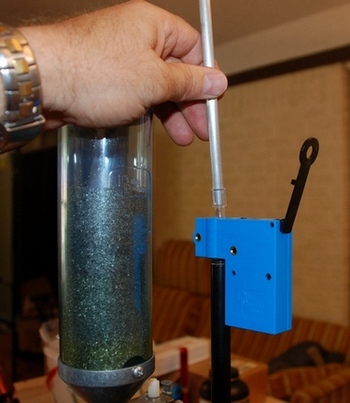

The primers are picked up in a hand held tube.

And dropped in the auto primer tube.

The primer alarm rod is added and the machine is ready to auto prime. It is worth noting that the weak spot in this machine as with most is in the primer system. More on that further down.

The Dillon RL550 set up for .45 ACP.

The Dillon RL550 at stage one: Bullet case at the first station. Here the case is resized and de-primed.

Stage 2: The case mouth is expanded and the case charged with powder.

Stage 3: Bullet is placed in the case mouth of the charged case. When the handle is pulled the bullet is seated.

Stage 4: The new bullet is final sized and crimped.

Finally the bullet is indexed out of the machine, down the chute and into the bullet tray, complete.

Done deal.

At this point, each time the handle is pulled, a bullet is completed.

Theoretically, this should be greasy fast. The only flaw in the theory is that for it to be fast, it also has to be trouble free. Any problem stops the progress and hence slows down the speed of the process.

And problems it does have.

Problems virtually every brand of reloading machine has. There are so many links in the primer system, and hence so many places something can and does go wrong are too numerous for me to have the endurance to list here.

The machine claims it can turn out 500-600 rounds per hour. Not if you're Superman on his best day with all machine accessory attachments in place. I have read real world reports of people making 400 per hour which if I was on Myth Busters would have to say is plausible, but not likely on a consistent basis.

So far, the best time I have logged moving at a pace that I would just not want to go much faster, I made 100 .45 ACP rounds in 17 minutes. Not too bad if I knew the machine could consistently run through 100 rounds at a time without the primer system failing. Again, theoretically, after set up I could make 300 rounds per hour including primer pickup. I just haven't had the machine run that long without problems somewhere in the priming system.

And they just happen all of a sudden. You go 25-30 rounds, get in the groove, and just when you think "ok, I'm movin now", squish, no primer feed. Every piece of the system has to be looked at to figure it out. And if it's internal, you have to take the primer system apart to fix it. And it generally messes up your bullet stages causing you to have to pull bullet casings.

At a price tag of around $400 for the machine, and a small fortune for tool heads, caliber conversion kits, dies, and spare parts for the primer pickup tubes , the machine comes in at nearly $700. And that means it should do what the manufacturer says it will do.

But it won't.

Even if some freak of nature speed monster could pull the handle that fast, the primer system would stop it far short of anything close to the claims.

I have to grudgingly say that the machine is still faster than the machine I've been using, in spite of the primer system. I can reload all the ammo that I need in a reasonable amount of time.

But for the price, Dillon would do well to take a look at the weak spots in this machine and do what they can to make sure it works smoothly at all stages. The price of the machine and necessary parts obligates them to do so, instead of acting like this thing is the God of all reloaders.

NOTE 11/29/2010: Maybe I'm just expecting more than I should from a machine like this. Maybe others that review it understand the issues with the priming system, and just consider it part of the process.

Others write to me swearing their machines are absolutely perfect. I don't know. I just know that a machine that consistently works perfectly for a few minutes, then breaks down in some part of the priming system, at least for this one, is far less than perfect.

And from the advice I've gotten from people who seem to "understand" and take in stride the imperfections, I would say they should expect more from a machine of this price.

Get the Armed Volunteer Church Security Guide - Now on Amazon Kindle.